Robotics Lab at ETH Zurich, Switzerland, has created a Robotic arm that can sculpt like an artist

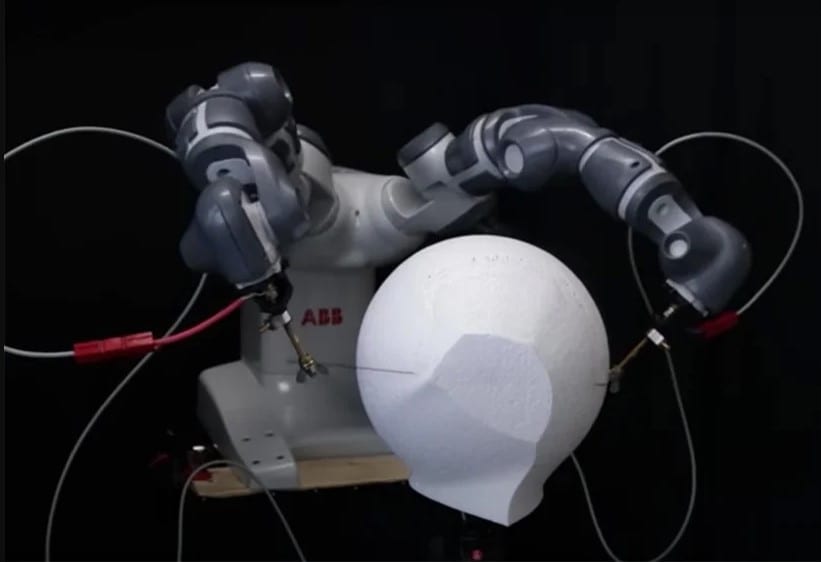

Researchers at ETH Zurich’s Computational Robotics Lab have created a robot, called RoboCut, that sculpts Styrofoam just like an artist.

RoboCut proposes a method that uses a dual-arm robot setup to actively control the shape of a flexible, heated rod as it cuts through the material. Conventional machines rely on straight wires and are thus limited to just creating geometrical pieces.

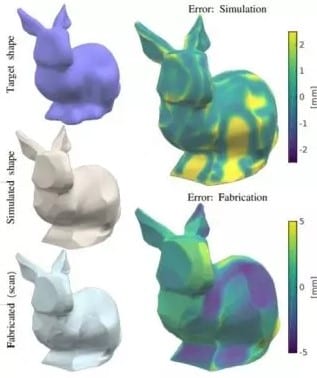

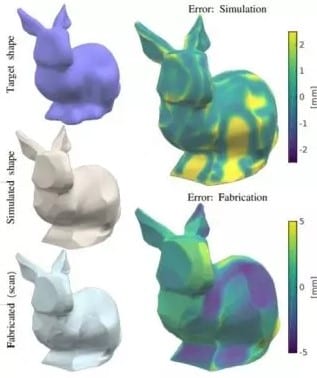

The process is now faster and more versatile, also require the software capability to calculate the curve and simulate the wire angles in the space with precision, giving it the ability to transform the Styrofoam into any shape with 80% accuracy. Souce: PDF

“With RoboCut, we enable robots to use deformable tools to efficiently fabricate complex objects with intricate curved shapes,” Simon Duenser, a Ph.D. student who worked on the project, told Digital Trends. “We apply this to a technique called hot wire cutting, a method where a heated wire is used to effortlessly cut through expanded polystyrene foam. While traditionally a straight wire would be used for this, in our case, the dual-arm robot uses a flexible rod. This allows it to continuously adapt the shape of the tool to match the curvature of the target surface, such that it can be produced more efficiently and with higher quality.”

The Computational Robotics Lab (CRL) is a research group within the Department of Computer Science at ETH Zurich, Germany. Led by Prof. Dr. Stelian Coros, focused on Computer Graphics, Robotics and Computational Fabrication.